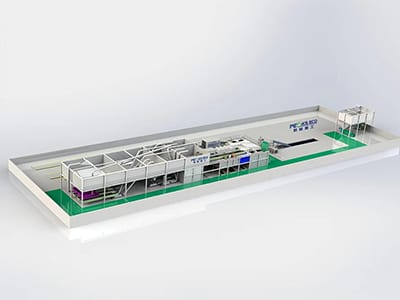

Comprehensive waste treatment and recycling system combines multiple waste processing technologies into a modern, collaborative solid waste management system.

This system effectively addresses the common issues in traditional pretreatment processes, such as high loss rates of organic matter and fats, as well as severe equipment wear.

PEAKS-ECO has developed a sustainable hydrometallurgical process that utilizes recycled liquid solvents to extract metals, delivering high-purity chemicals back into the battery supply chain.

Supported by Qunfeng Machinery’s patented pyrolysis technology, waste tires can be efficiently and sustainably transformed into multiple high-value secondary raw materials.

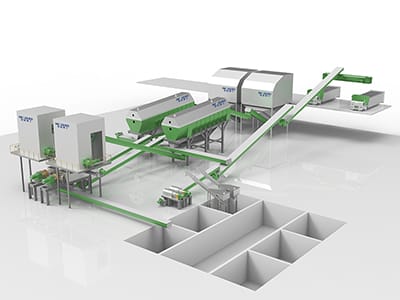

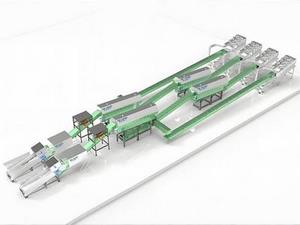

To effectively manage sorted recyclable waste, PEAKS-ECO has developed an independent process line.

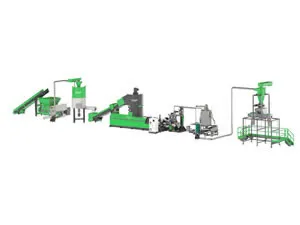

The plastic granulation line can process waste plastics such as polyethylene (PE), polypropylene (PP), polystyrene (PS), and acrylonitrile-butadiene-styrene (ABS) into recycled products in film, rigid, or foam form after cleaning.

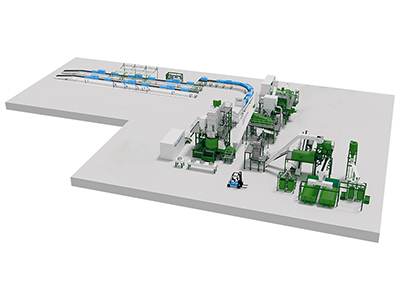

The waste sorting plant for construction waste is designed to convert construction waste into reusable materials.

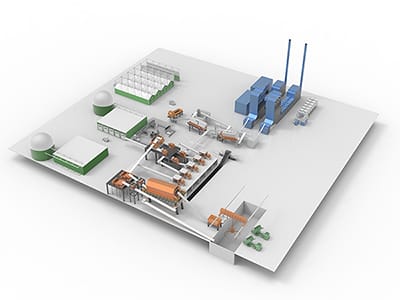

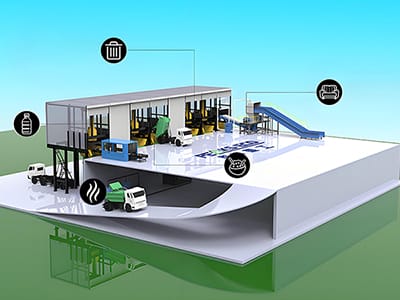

Municipal waste, also known as household waste, is most often comprised of discarded daily consumables and contains a mixture of wet and dry recyclable materials, organic and inorganic materials, and biodegradable materials.

Stale garbage refers to remaining non-degradable garbage that has been in landfills for long periods of time and has not broken down.

Urban household waste is ubiquitous, and PEAKS-ECO has developed waste-to-energy incineration equipment and systems that achieve high resource utilization efficiency and economic benefits.

The mechanical biological treatment (MBT) system consists of a mechanical sorting system, a biological anaerobic digestion (AD) system and a sewage treatment system.

With a processing capacity of 100-2000 tons per day, our waste transfer station performs unloading, pre-screening, removal of inappropriate items, waste compacting and reloading, then transfer of processed waste to the appropriate locations.

Integrated waste management plant serves as a multifunctional platform that incorporates various operations.

After undergoing harmless and stabilization treatment, sludge can be utilized in various industries such as agriculture and manufacturing, achieving both environmental protection and resource recovery goals.

We own and operate two production facilities for the manufacturing of waste sorting, waste transferring, and waste incineration equipment.

This factory is divided into five production workshops outfitted with an array of processing equipment to keep up with production demands. The workshops include a steel structure workshop, weighing apparatus workshop, manufacturing workshop for waste separation equipment, a production workshop for conveyor belts, and a manufacturing workshop for waste transferring equipment.

After raw materials have been purchased, we carry out independent sampling inspections to test their ductility, strength, rust resistance, and the surface quality of steel plate.

Purchased motors undergo 24-hour idling test and other accessories are inspected by our highly skilled specialists.

Our special quality inspection team conducts a series of detailed inspections regarding welding processing, assembly, and painting quality of products periodically.

Each device will undergo fatigue testing prior to delivery.

The final inspection on these products involves the examination of painting and welding quality.

Here at Qunfeng, we are dedicated to providing customers with outstanding equipment backed up by all-around services. Once your equipment has been installed our support team is here to help you keep it running optimally.

Services we offer:

We provide comprehensive installation services upon request where we will offer instructions or remote guidance.

Once the equipment has been installed, our commissioning engineers can be dispatched to provide your operators with professional training so you can understand and take full advantage of all the functions and applications of the machinery.

We have sales and service centers throughout the Middle East, Europe, and Southeast Asia to best serve customers.

Qunfeng maintains a large inventory of key components, allowing us to send you replacement parts in a timely manner.